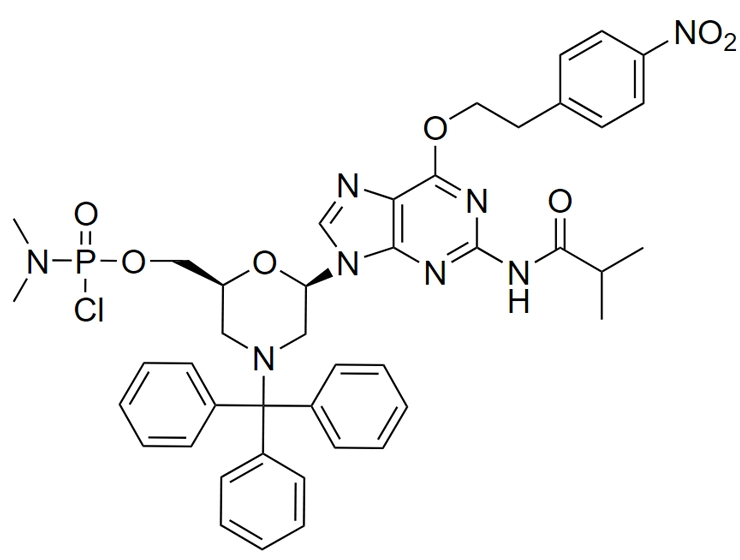

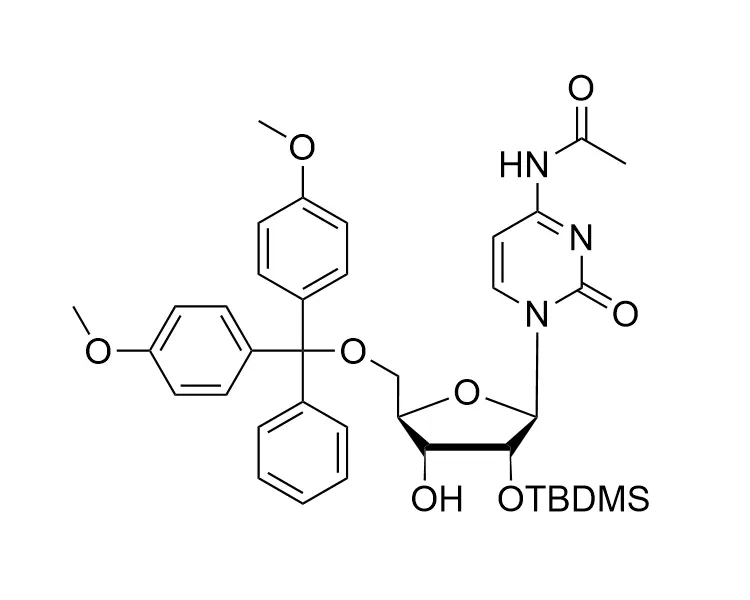

The synthesis of trimer phosphoramidites represents a critical aspect of industrial processes, particularly in the realm of nucleic acid chemistry. These compounds play a pivotal role in the efficient and scalable production of oligonucleotides, which find applications in various fields, including medicine, agriculture, and biotechnology. However, this synthesis is not without its challenges, necessitating a nuanced understanding of the hurdles involved and the development of innovative solutions.

Challenges in Scalable Synthesis

Complex Reaction Pathways

The synthesis of trimer phosphoramidites involves intricate reaction pathways that require precise control over multiple reaction steps. Achieving scalability while maintaining high yields becomes a significant challenge due to the increased likelihood of side reactions and undesired by-products. Controlling these pathways to ensure reproducibility on an industrial scale demands a comprehensive understanding of the underlying chemistry.

Purification and Isolation

As the scale of synthesis increases, the purification and isolation of trimer phosphoramidites become increasingly challenging. Traditional purification techniques, such as column chromatography, may not be efficient or cost-effective on an industrial scale. Developing scalable purification methods that ensure high purity and yield is crucial for the successful implementation of trimer phosphoramidites in large-scale applications.

Economic Viability

The synthesis of trimer phosphoramidites often involves the use of expensive reagents and catalysts. Scaling up the process while maintaining economic viability poses a significant hurdle. The high cost of raw materials, coupled with the need for specialized equipment, necessitates the development of cost-effective strategies to make the synthesis economically feasible for large-scale production.

Solutions to Overcome Challenges

Advanced Reaction Engineering

In addressing the complexity of reaction pathways, advanced reaction engineering techniques such as flow chemistry and continuous processing offer solutions. These methods allow for precise control over reaction parameters, minimizing side reactions and improving reproducibility. Implementing these advanced techniques can enhance the scalability of trimer phosphoramidite synthesis.

Innovative Purification Strategies

To overcome purification challenges, the development of innovative purification strategies is essential. Technologies such as simulated moving bed chromatography and solid-phase extraction can be explored for their potential in large-scale purification processes. These approaches aim to streamline purification steps, reduce solvent usage, and improve overall efficiency.

Green Chemistry Approaches

Addressing the economic viability of trimer phosphoramidite synthesis involves adopting green chemistry principles. Exploring sustainable and environmentally friendly synthesis routes, as well as recycling and reusing certain reaction components, can contribute to cost reduction. Additionally, the development of catalysts that are both efficient and economical is crucial for achieving a balance between cost and performance.

The scalable synthesis of trimer phosphoramidites presents both challenges and opportunities for innovation in industrial applications. By understanding and addressing the complexities associated with reaction pathways, purification processes, and economic considerations, researchers and industry professionals can pave the way for the widespread use of trimer phosphoramidites in diverse fields. As advancements continue, the integration of scalable and cost-effective synthesis methods will undoubtedly contribute to the broader impact of these compounds on science, medicine, and technology.

En

En Cn

Cn